V-pulleys are indispensable components in power transmission systems across diverse sectors, including agriculture and industry. However, V-pulleys designed for agricultural machinery and industrial applications exhibit distinctive characteristics to meet specific operational requirements. By understanding these disparities, we can appreciate how these specialized components contribute to efficient power transmission, enhanced productivity, and reliability in their respective domains.

Design and Construction :

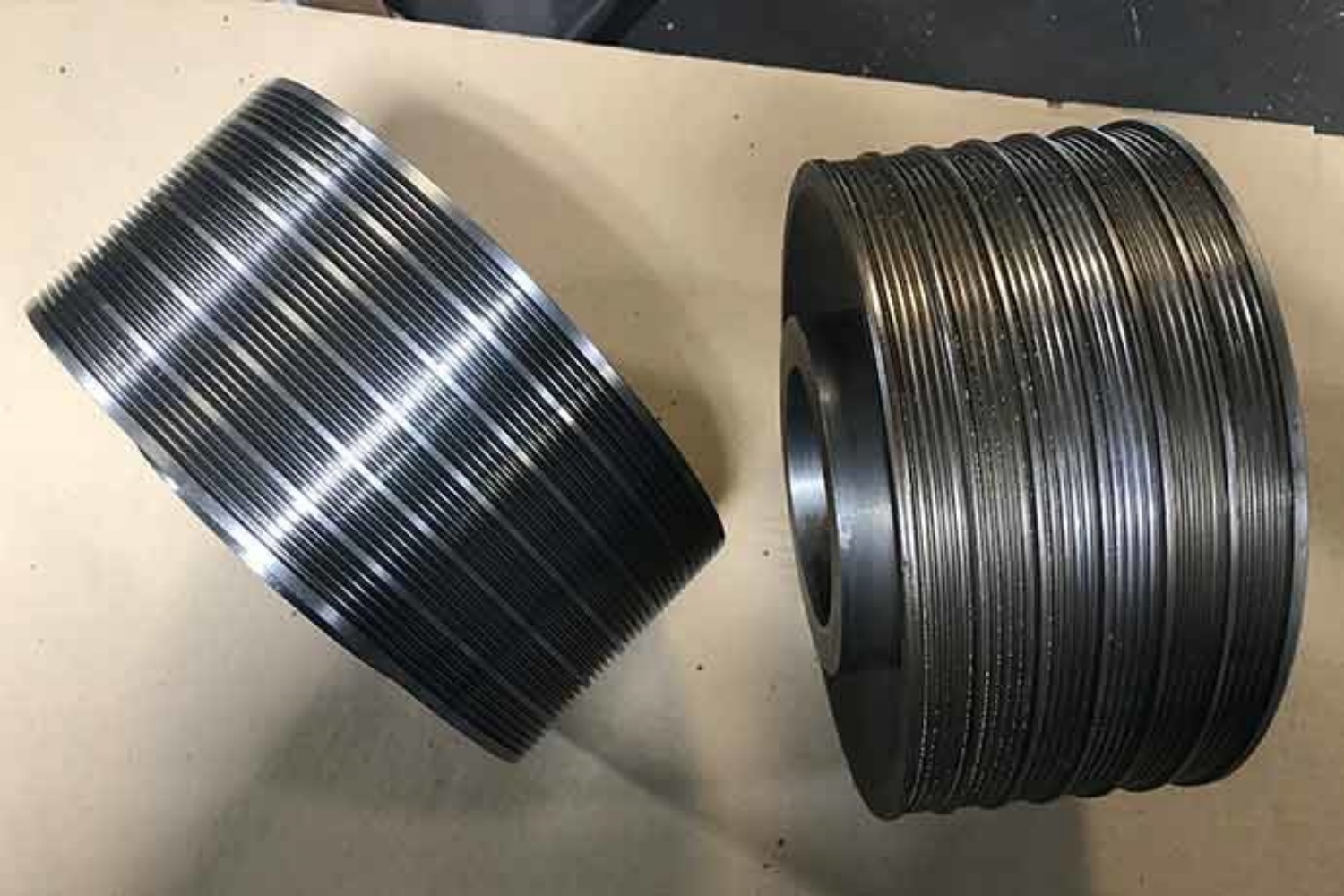

V-pulleys for agriculture and industry differ in their design and construction to align with the distinct demands of each sector. Agricultural V-pulleys are often built to withstand harsh outdoor environments, such as exposure to moisture, dust, and debris. They are frequently coated with corrosion-resistant materials to endure adverse weather conditions. Conversely, V-pulleys for industrial applications prioritize precision engineering to ensure smooth power transmission within closed systems. Their construction may include robust materials like steel or aluminum, emphasizing strength and durability.

Load Capacity and Power Transmission :

The load capacity and power transmission requirements vary significantly between agriculture and industrial sectors. Agricultural V-pulleys are engineered to handle varying loads encountered during different farming tasks, such as plowing, harvesting, or seeding. They are designed for efficient power transfer in equipment like tractors, combines, and harvesters. In contrast, industrial V-pulleys cater to a wide array of machinery in manufacturing facilities, conveying systems, and processing units. Their load capacities are tailored to the specific demands of industrial equipment, ranging from light-duty to heavy-duty applications.

Size and Dimensional Variation :

V-pulleys for agriculture and industry exhibit differences in size and dimensional variation. Agricultural V-pulleys often come in larger sizes, catering to the scale of farming equipment and the power required to operate farm machinery. Conversely, industrial V-pulleys can vary widely in size, depending on the specific application and power transmission requirements in manufacturing processes.

Belt Type and Compatibility :

Agricultural and industrial applications use different types of belts, and thus, the V-pulleys must be compatible with their corresponding belts. Agricultural V-pulleys are commonly used with V-belts or agricultural belts designed for superior grip and power transmission in farming equipment. Industrial V-pulleys, on the other hand, accommodate a wide range of belt types, such as timing belts, synchronous belts, or V-belts, depending on the industrial machinery and its unique requirements.

Operational Environment :

The operational environment of agricultural and industrial sectors plays a significant role in determining the features and materials of V-pulleys. Agricultural V-pulleys are tailored to endure outdoor conditions, including exposure to dirt, debris, and moisture. They often have protective coatings to resist rust and corrosion. Industrial V-pulleys, operating within enclosed environments, prioritize precision, balance, and reduced noise levels to ensure smooth functioning and productivity in industrial processes.

Lubrication and Maintenance :

Agricultural V-pulleys may require more frequent maintenance due to the challenging outdoor environment they encounter. Regular lubrication and cleaning are crucial to ensure their smooth operation and longevity. Industrial V-pulleys, operating in controlled environments, may require less frequent maintenance, but still demand proper lubrication and periodic inspections to sustain their efficiency and service life.

Conclusion :

V-pulleys for agriculture and industry serve as critical components in power transmission systems, each tailored to meet the specific demands of its respective sector. The distinctive design, construction, load capacity, size, compatibility, and maintenance requirements cater to the unique operational conditions and power transmission needs of agriculture and industry. By appreciating the differences between these specialized V-pulleys, agricultural and industrial sectors can select the most suitable components to ensure efficient power transmission, enhance productivity, and uphold reliability in their equipment and machinery.

CONTINUE READING

Related Posts

V-belt pulleys play a crucial role in electric motor systems, providing the necessary power transmission to drive various machinery and […]

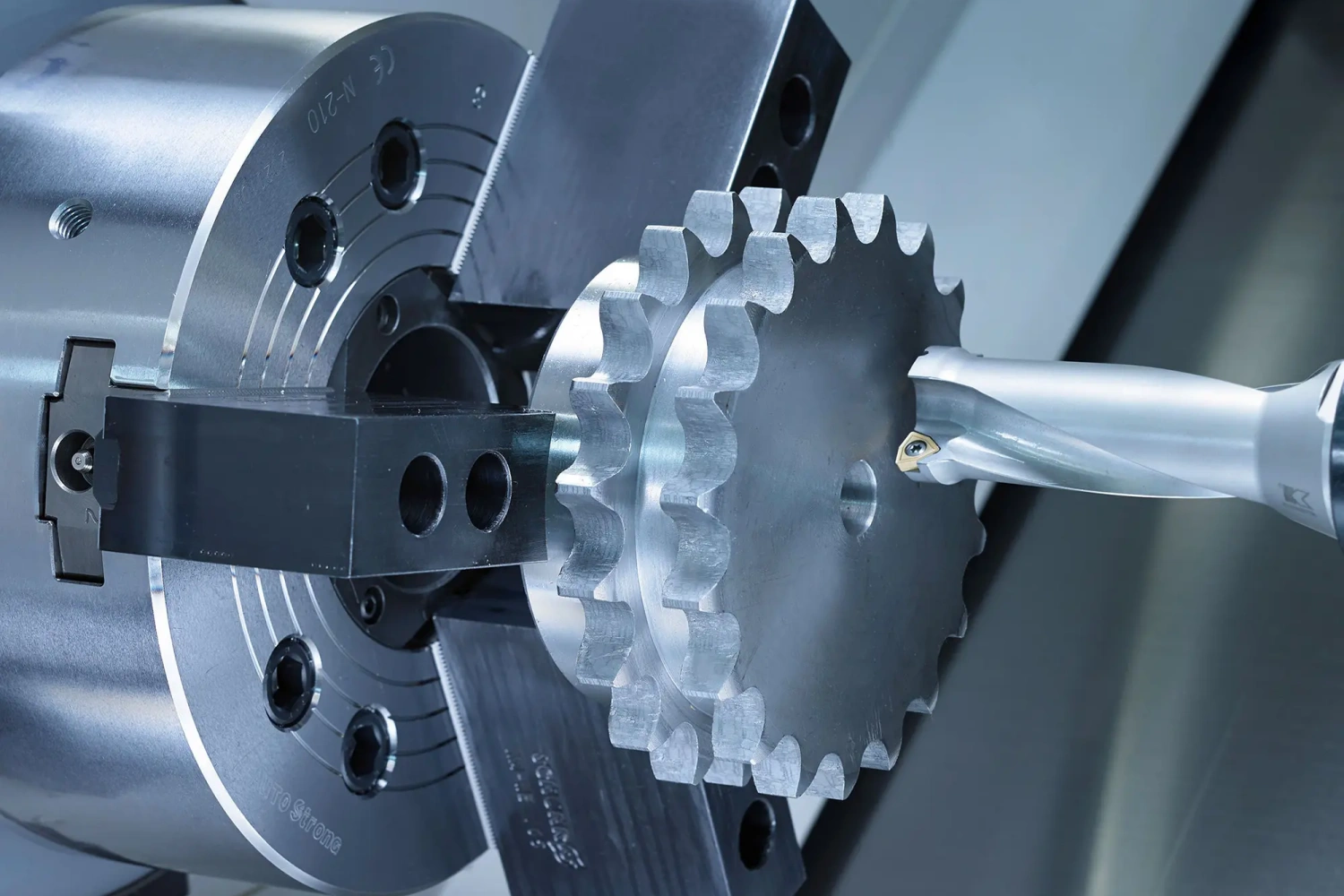

Industrial sprockets are indispensable components across a wide array of industries, serving critical roles in transmitting power and enabling mechanical […]

Industrial gears are a crucial component in various machines and industrial processes. They are used for transmitting power and motion […]