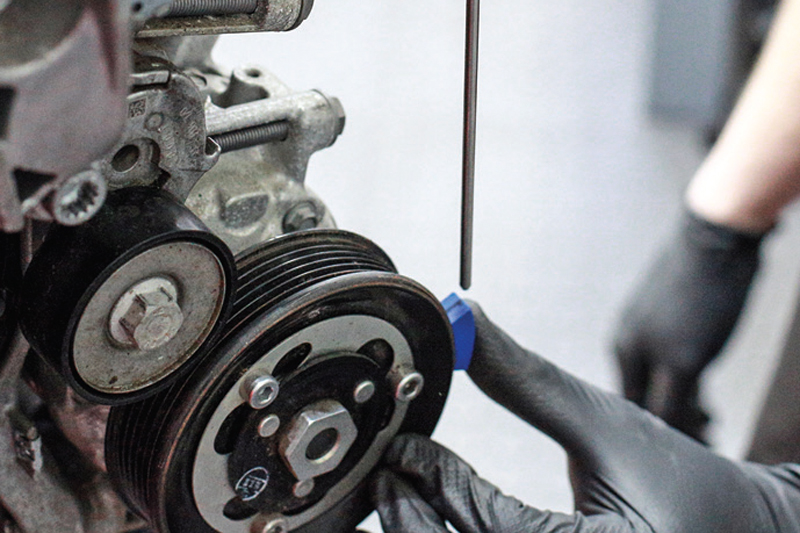

Motor belts and pulleys are components used in power transmission systems to transfer power from a motor to other rotating equipment such as fans, pumps, and compressors. The motor belt is a flexible looped component made of synthetic materials such as rubber, neoprene, or urethane that connects the motor shaft to the pulley. The pulley, on the other hand, is a rotating component that is mounted on the driven equipment’s shaft and receives power from the motor belt. Here are some characteristics and differences between motor belts and pulleys.

Characteristics of Motor Belts:

- Motor belts are flexible bands made of various materials such as rubber, polyurethane, or neoprene.

- They come in a wide range of sizes and lengths to fit different motor sizes and applications.

- They can transmit power over long distances with minimal energy loss.

- Motor belts can absorb shocks and vibrations, which makes them ideal for use in machines that operate under varying load conditions.

- They require less maintenance compared to other power transmission components.

Characteristics of Motor Pulleys:

- Motor pulleys are typically made of metal such as steel or aluminum.

- They come in different shapes and sizes to accommodate different belt sizes and applications.

- They are mounted on the motor shaft and transmit power to the belt.

- Motor pulleys can be designed to adjust the speed of the driven machine by changing the pulley size or using a variable speed pulley.

- They require regular maintenance to prevent wear and tear, which can lead to belt slippage or failure.

Differences between Motor Belts and Pulleys:

What is the difference between the material and power system of motor belt and pulley?

- Motor belts are flexible bands while motor pulleys are rigid components.

- Motor belts transmit power by frictional contact with the pulley while motor pulleys transmit power through a mechanical connection with the belt.

- Motor belts come in different sizes and lengths while motor pulleys come in different sizes and shapes.

- Motor belts require less maintenance compared to motor pulleys.

- Motor pulleys can be used to adjust the speed of the driven machine, while motor belts cannot be adjusted to change the speed of the driven machine.

What are the application scope of motor belts and pulleys?

- Motor belts and pulleys are commonly used in a variety of industrial and commercial applications, including:

- Conveyor systems: Motor belts and pulleys are used to power conveyor belts that move materials in factories, warehouses, and other industrial facilities.

- HVAC systems: Motor belts and pulleys are used to power the fans that circulate air in heating, ventilation, and air conditioning systems.

- Agricultural equipment: Motor belts and pulleys are used in farming equipment such as tractors, harvesters, and combines to power various agricultural functions.

- Automotive: Motor belts and pulleys are used in car engines to power various components such as the alternator, power steering pump, and air conditioning compressor.

- Construction equipment: Motor belts and pulleys are used in heavy-duty construction equipment such as cranes, bulldozers, and excavators to power various functions.

CONTINUE READING

Related Posts

In mechanical drives, gears are essential for transmitting motion, power, and torque across various applications. Two of the most commonly […]

In the world of industrial machinery, efficiency, precision, and reliability are essential. A key component in achieving these goals is […]

In the world of industrial engineering, precision and innovation are essential to staying competitive and meeting the ever-growing demands of […]