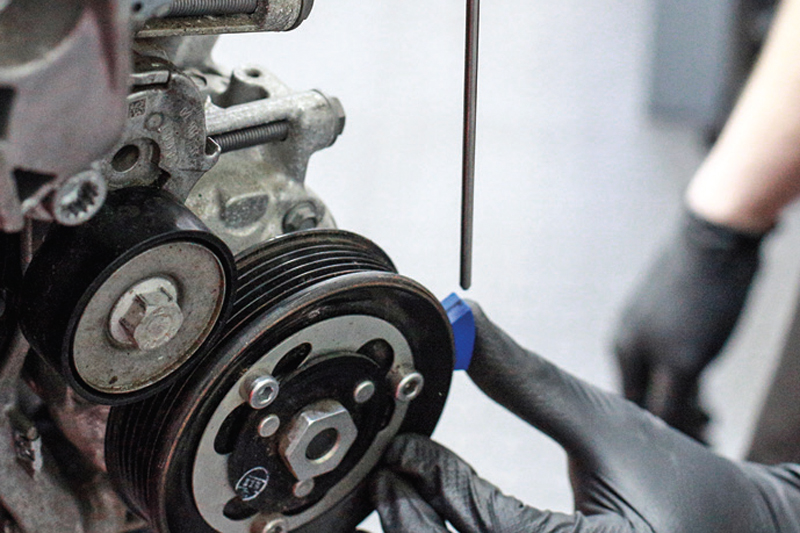

A motor pulley is a type of pulley that is attached to the motor shaft and is used to transfer power to another pulley, such as a belt pulley or a sheave. Motor pulleys can be made from a variety of materials, including aluminum, steel, and cast iron.

A motor pulley v belt is a type of pulley that is specifically designed to work with a V-belt. V-belts are designed to fit into the grooves of the pulley, creating a secure and efficient transfer of power. Motor pulley v belts are typically made from materials such as cast iron or steel, and come in a range of sizes to fit different motors and V-belt sizes.

The appropriate motor pulley and v belt depend on the specific application and the power transmission requirements. Here are some general guidelines for selecting the appropriate motor pulley and v belt:

- Determine the required speed ratio: The motor pulley and v belt should be selected based on the required speed ratio between the motor and the driven shaft.

- Calculate the required torque: The motor pulley and v belt should be selected based on the required torque for the application.

- Determine the center distance: The center distance between the motor and the driven shaft should be measured to ensure that the motor pulley and v belt are properly sized.

- Consider the load conditions: The motor pulley and v belt should be selected based on the load conditions of the application, including the type and magnitude of the load.

- Choose the appropriate v belt type: There are different types of v belts available, such as V-belts, wedge belts, and synchronous belts. The appropriate type should be selected based on the application requirements.

- Consider the material and design: The motor pulley and v belt should be made from high-quality materials and designed to provide reliable power transmission and long service life.

It is recommended to consult with a qualified engineer or supplier to select the appropriate motor pulley and v belt for your specific application to ensure reliable and efficient power transmission.

What are the characteristics of motor pulley and motor pulley v belt ?

The characteristics of a motor pulley and a motor pulley V-belt are:

- Material: Motor pulleys and V-belt pulleys can be made from a variety of materials, such as cast iron, steel, aluminum, or plastic. The choice of material can affect the strength, durability, and weight of the pulley.

- Size: The size of a motor pulley or a motor pulley V-belt refers to the diameter of the pulley. The size can affect the speed and power output of the motor.

- Number of grooves: The number of grooves in a motor pulley or a motor pulley V-belt can affect the performance of the motor, as it determines the number of belts that can be used with the pulley.

- Design: The design of the pulley can affect its efficiency and power transmission. For example, V-belt pulleys have a V-shaped groove that helps the belt grip the pulley more tightly, reducing slippage and improving power transmission.

- Compatibility: Motor pulleys and V-belt pulleys need to be compatible with the motor and the belt being used. The pulley should have the right bore size, keyway, and other dimensions to fit properly.

- Price: The price of motor pulleys and motor pulley V-belts can vary depending on the material, size, design, and brand.

Overall, motor pulleys and motor pulley V-belts are critical components of a motor system, and their selection should be based on the specific application requirements, including power, speed, and efficiency.

CONTINUE READING

Related Posts

In mechanical drives, gears are essential for transmitting motion, power, and torque across various applications. Two of the most commonly […]

In the world of industrial machinery, efficiency, precision, and reliability are essential. A key component in achieving these goals is […]

In the world of industrial engineering, precision and innovation are essential to staying competitive and meeting the ever-growing demands of […]