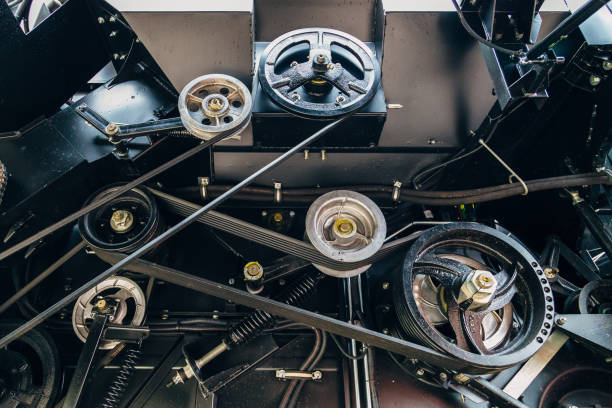

Agricultural pulleys and industrial pulleys share some common characteristics, such as being used for power transmission and generally being made of durable materials such as cast iron or steel. However, there are some differences between the two types of pulleys.

What are the characteristics of industrial belt pulley ?

Industrial belt pulleys are specifically designed for high-performance and heavy-duty applications in various industries. The following are some of the key characteristics of industrial belt pulleys:

- Material: Industrial pulleys are typically made of strong and durable materials such as cast iron, steel, or aluminum to withstand high loads and stress.

- Size: Industrial pulleys are available in a wide range of sizes and shapes to fit different types of belts and machines.

- Precision: Industrial pulleys are machined to high levels of precision to ensure smooth and efficient operation.

- Load-bearing capacity: Industrial pulleys are designed to handle heavy loads and transmit high power between the drive and driven components.

- Resistance to wear and tear: Industrial pulleys are resistant to wear and tear caused by constant friction and stress.

- Flexibility: Some industrial pulleys are designed to be adjustable or have variable speed capabilities, providing greater flexibility in changing operating conditions.

- Cost: Industrial pulleys can be more expensive than ordinary pulleys due to their specialized design and material requirements.

Overall, industrial belt pulleys are designed to provide high performance and reliability in demanding industrial applications.

What are the characteristics of agricultural pulley

Agricultural pulleys, also known as farm pulleys, are used in agricultural machinery and equipment such as tractors, combines, and irrigation systems. They have some specific characteristics that make them suitable for the harsh and demanding conditions in the agricultural industry. Here are some of the characteristics of agricultural pulleys:

- Durability: Agricultural pulleys are designed to withstand the harsh conditions in the field. They are made of durable materials such as cast iron or steel.

- High load capacity: These pulleys are designed to handle high loads, making them suitable for heavy-duty applications.

- Corrosion resistance: Agricultural pulleys are often exposed to moisture and other corrosive elements. To prevent rust and corrosion, they are typically coated with a protective layer or made of corrosion-resistant materials.

- Reliable performance: Agricultural pulleys are designed to deliver reliable performance in the field, ensuring that farm equipment operates smoothly and efficiently.

- Versatility: Agricultural pulleys come in a variety of sizes and designs to fit different equipment and applications.

- Cost-effective: Agricultural pulleys are typically less expensive than specialized industrial pulleys, making them a cost-effective solution for farmers and agricultural businesses.

Overall, agricultural pulleys are designed to withstand the tough conditions of the farming industry while delivering reliable performance and durability.

Overall, the main difference between agricultural and industrial pulleys lies in their design and application. Agricultural pulleys are designed for use in farm machinery and are typically larger and heavier duty than industrial pulleys, while industrial pulleys are used in a wide range of applications and are designed to handle high-speed and high-torque requirements.

CONTINUE READING

Related Posts

Agricultural machinery plays a vital role in modern farming, contributing to increased efficiency, productivity, and profitability. At the heart of […]

Chain sprockets are an integral component in a wide range of mechanical systems, playing a crucial role in transmitting power […]

Conveyor systems are the backbone of many industries, facilitating the efficient movement of materials across manufacturing floors, warehouses, and distribution […]