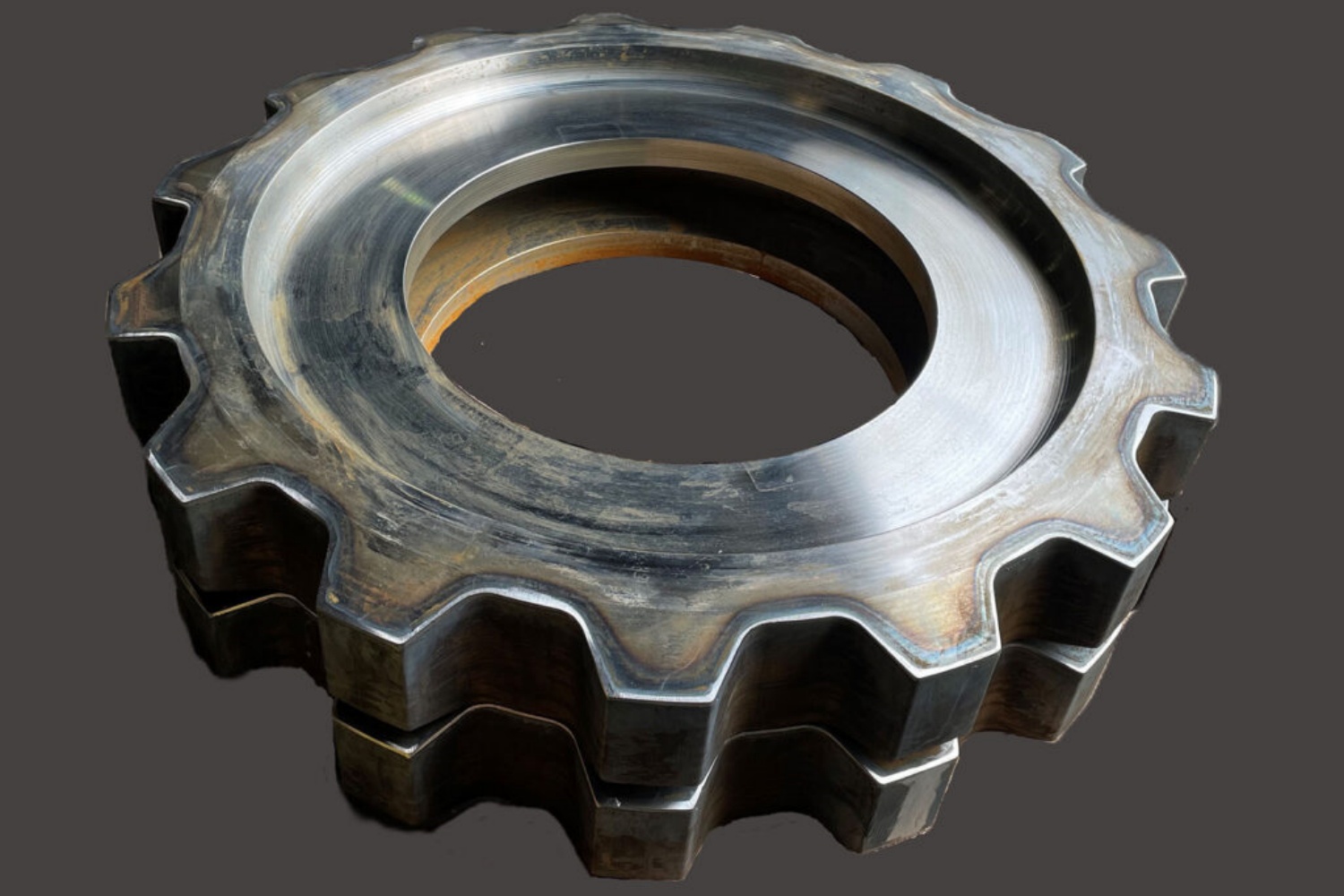

Pulley and V-belt pulley are both types of mechanical power transmission components used to transmit rotary motion between two shafts. The primary difference between them is the type of belt used to transfer power.

Similarities:

- Both are used to transmit power between two shafts

- Both require proper alignment and tensioning to work effectively

- Both come in a variety of sizes, materials, and designs to suit different applications

Differences:

- Pulleys use flat belts or ribbed belts, while V-belt pulleys use V-belts, which are wider at the base and narrower at the top, creating a wedge-shaped profile that improves grip and power transmission.

- V-belt pulleys are better suited for high-speed applications than pulleys because they provide more traction and grip, while pulleys are better suited for low-speed applications where smooth operation and reduced noise are important.

- V-belt pulleys require more careful alignment than pulleys due to their design, as misalignment can cause belt slippage and reduce power transmission efficiency.

- V-belt pulleys are generally more expensive than pulleys due to their more complex design and manufacturing process.

How to select suitable pulley and V-belt pulley ?

To select a suitable pulley or V-belt pulley, you need to consider the following factors:

- Type of application: Different applications require different types of pulleys. For example, a V-belt pulley is used in applications where the load is moderate to heavy, while a flat belt pulley is used in applications where the load is light.

- Power transmission requirements: The amount of power that needs to be transmitted between the motor and the driven equipment is an important factor to consider. This will determine the size and type of pulley needed.

- Belt size: The size of the belt being used also determines the size of the pulley needed. It’s important to select a pulley that is compatible with the belt size.

- Speed ratio: The speed ratio between the driving pulley and the driven pulley is an important factor to consider. This determines the amount of torque and speed needed for the application.

- Material: The material of the pulley is also an important factor to consider. The material should be able to withstand the load and environment of the application. For example, a cast iron pulley is suitable for heavy-duty applications.

- Shaft size: The shaft size of the pulley should match the shaft size of the motor or driven equipment.

- Budget: The cost of the pulley is also an important factor to consider. It’s important to select a pulley that meets your budget while still meeting the requirements of the application.

In summary, when selecting pulley and V-belt pulley, the selection depends on the application requirements, such as speed, torque and power transmission. If the application involves high speed and high power transmission, V-belt pulley is usually a better choice because they have excellent grip and traction. If the application involves low speed operation and noise reduction is important, pulley may be a better choice. Proper alignment and tension should also be considered in the selection process to ensure efficient and effective power transmission.

CONTINUE READING

Related Posts

In the dynamic landscape of mechanical engineering, spline shafts have played a pivotal role in power transmission and motion control. […]

In the world of industrial machinery, sprockets play a critical role in the efficiency, performance, and durability of various equipment. […]

Conveyor sprockets are vital in material handling systems, driving the chains and belts that transport products across various industries. In […]