Belt pulleys, wheel pulleys, and sheaves are all types of pulleys, which are mechanical devices that are used to transmit power or change the direction of a force. Although these devices are similar in function, they have some differences in terms of their design and application.

Belt pulleys are generally flat, circular disks with a groove around the circumference that is designed to accommodate a belt. They are often used in applications that require the transfer of power from one component to another using a belt. Belt pulleys are typically used in applications such as engine belts in cars or other vehicles, industrial machinery, and other equipment that requires the transfer of power from one rotating shaft to another.

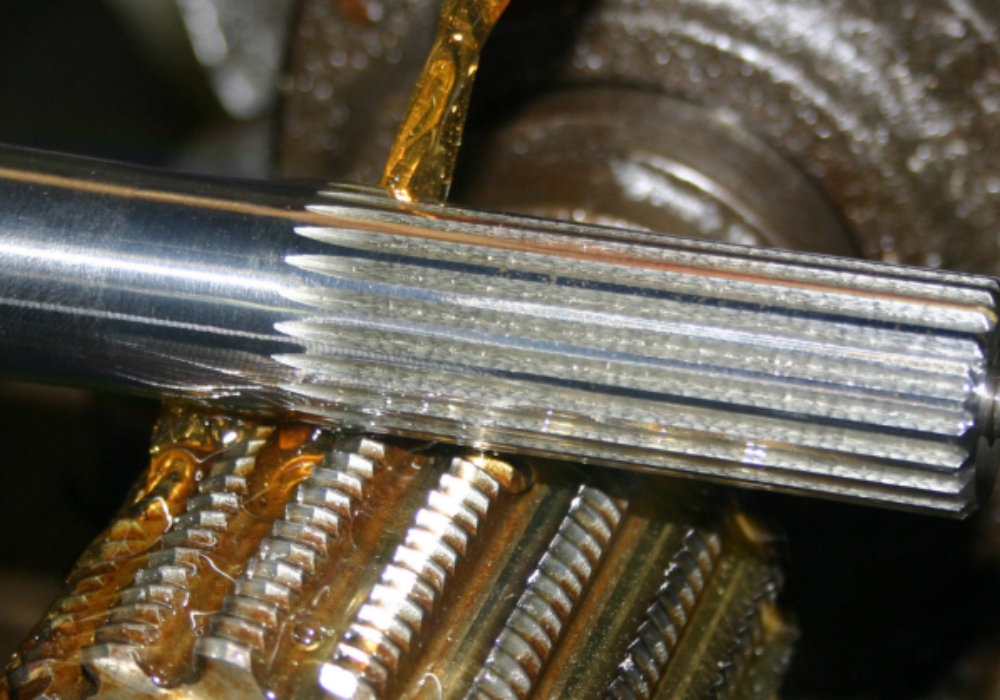

Wheel pulleys, also known as gear pulleys or sprockets, are similar to belt pulleys in shape but have teeth or cogs around the circumference that engage with another wheel or chain to transfer torque and power more efficiently. Wheel pulleys are commonly used in applications such as bicycles, motorcycles, and other machinery that requires a more efficient transfer of power than a simple belt pulley can provide.

Sheaves, also known as pulley blocks, are designed to redirect the direction of a force. They often consist of a grooved wheel and a rope or cable that runs through the groove. Sheaves are used in various applications, such as in cranes, lifts, and other heavy-duty machinery, where they can help to change the direction of a load or distribute weight more evenly.

In summary, while all three types of pulleys are used to transmit power or change the direction of a force, they are each designed to perform specific tasks. Belt pulleys are used to transfer power from one component to another using a belt, wheel pulleys are used to transfer torque and power more efficiently using teeth or cogs, and sheaves are used to redirect the direction of a force in heavy-duty machinery.

Belt pulleys, wheel pulleys, and sheaves can be made from a variety of materials depending on the specific application and the desired properties of the pulley. Some common materials used for these devices include:

- Steel: Steel is a common material for pulleys, as it is strong, durable, and can handle heavy loads. It is also relatively affordable and can be easily machined to create the desired shape and size.

- Aluminum: Aluminum is lightweight and has good corrosion resistance, making it a good choice for applications where weight and resistance to environmental factors are important. It is also easy to machine and can be an affordable option.

- Brass: Brass is a relatively soft metal that is often used in applications where the pulley needs to be gentle on the belt or rope it is interacting with. It is also resistant to corrosion and has good electrical conductivity.

- Cast iron: Cast iron is a strong and durable material that is often used for large, heavy-duty pulleys. It is resistant to wear and can handle high temperatures, making it a good choice for industrial applications.

- Plastic: Plastic pulleys are lightweight, corrosion-resistant, and can be an affordable option for some applications. They are often used in applications where weight is a concern, such as in robotics and other lightweight machinery.

In summary, the material used for belt pulleys, wheel pulleys, and sheaves will depend on the specific application and the desired properties of the pulley, such as strength, durability, weight, and resistance to corrosion or wear.

CONTINUE READING

Related Posts

In the world of machinery and mechanical systems, precision is key. Spline shafts play a crucial role in ensuring that […]

Spline shafts are critical components in various machinery and equipment, playing a pivotal role in power transmission and torque distribution. […]

Custom Gears: Where Precision Meets the Unique Demands of Your Industry In the intricate world of machinery and power transmission, […]