Sprockets and pulleys are both used in power transmission systems to transmit rotary motion from one component to another. , but they differ in several key ways.

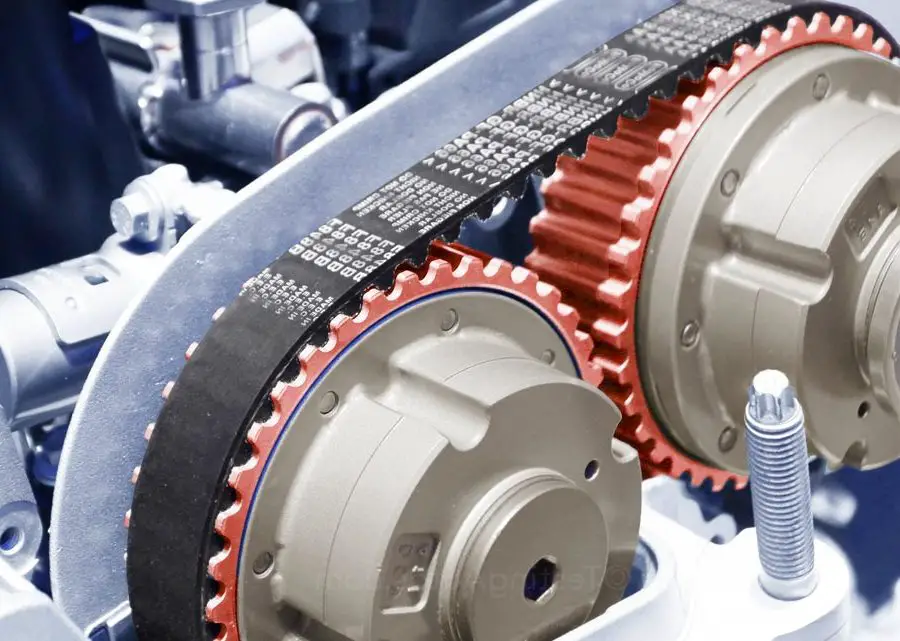

- Shape: Sprockets are generally disc-shaped with teeth along the edge that mesh with a chain, while pulleys are typically cylindrical or conical with a groove around the circumference that accepts a belt.

- Power transmission: Sprockets are used to transmit power between a chain and a rotating shaft, while pulleys are used to transmit power between a belt and a rotating shaft.

- Chain or belt type: Sprockets are designed to work with a specific type of chain, while pulleys are designed to work with a specific type of belt. The choice of chain or belt type depends on the requirements of the application, such as load capacity, speed, and environmental conditions.

- Tensioning: Sprockets do not require tensioning because the chain maintains a constant tension, while pulleys require tensioning to maintain the proper belt tension for efficient power transmission.

- Lubrication: Sprockets typically require lubrication to reduce friction and wear between the chain and teeth, while pulleys require little or no lubrication.

Application of Sprockets and pulleys

Sprockets are typically used in conjunction with roller chains to transmit power between a chain and a rotating shaft. Sprockets are commonly used in applications such as bicycles, motorcycles, industrial machinery, and conveyor systems. Some specific applications of sprockets include:

- Bicycle and motorcycle chains: Sprockets are used in conjunction with chains to transmit power from the pedals or engine to the rear wheel.

- Industrial machinery: Sprockets are used in various types of machinery to transmit power between rotating shafts, such as in conveyor systems or printing presses.

- Agricultural equipment: Sprockets are used in various types of farm equipment to transmit power from the tractor to various implements, such as plows or cultivators.

- Pulleys, on the other hand, are typically used with belts to transmit power between a belt and a rotating shaft. Pulleys are commonly used in applications such as automotive engines, HVAC systems, and industrial machinery. Some specific applications of pulleys include:

- Automotive engines: Pulleys are used to drive various components, such as the alternator, water pump, and power steering pump, from the engine’s crankshaft.

- HVAC systems: Pulleys are used in air conditioning and heating systems to drive the compressor and other components.

- Industrial machinery: Pulleys are used in various types of machinery to transmit power between rotating shafts, such as in conveyor systems or printing presses.

Both sprockets and pulleys are available in a range of sizes and materials to meet specific application requirements. The choice between a sprocket and a pulley will depend on the specific requirements of the application, such as load capacity, speed, and environmental conditions.

In summary, the main difference between sprockets and pulleys is the type of power transmission system they work with (chain or belt) and the shape and design of the component. The choice between a sprocket and a pulley will depend on the specific requirements of the application, such as load capacity, speed, and environmental conditions.

CONTINUE READING

Related Posts

In the world of agriculture, the efficiency and reliability of machinery play a pivotal role in ensuring high productivity and […]

In today’s world, industry’s need for sustainable solutions has never been greater. With growing environmental concerns and global efforts to […]

In the field of agriculture, proper equipment is essential for achieving sustainable growth. Among the various components of agricultural machinery, […]