A DC motor is a type of electric motor that converts direct current electrical power into mechanical power. It works by using the interaction between magnetic fields and electric currents to produce rotational motion. DC motors are commonly used in a variety of applications, including vehicles, machinery, and robotics. They can be found in various sizes, from small hobby motors to large industrial motors, and they can operate at various speeds and power levels. DC motors are popular due to their simple design, reliability, and ease of control.

How to make pulley for dc motor ?

The manufacturing process for a DC motor pulley may vary depending on the specific design and materials used. However, a general process may include the following steps:

- Purpose : Determine the size and specifications of the pulley required for your DC motor based on its intended use.

- Material selection: The material for the pulley is selected based on the required strength, durability, and other properties. Common materials used for pulleys include aluminum, steel, cast iron, and plastic.

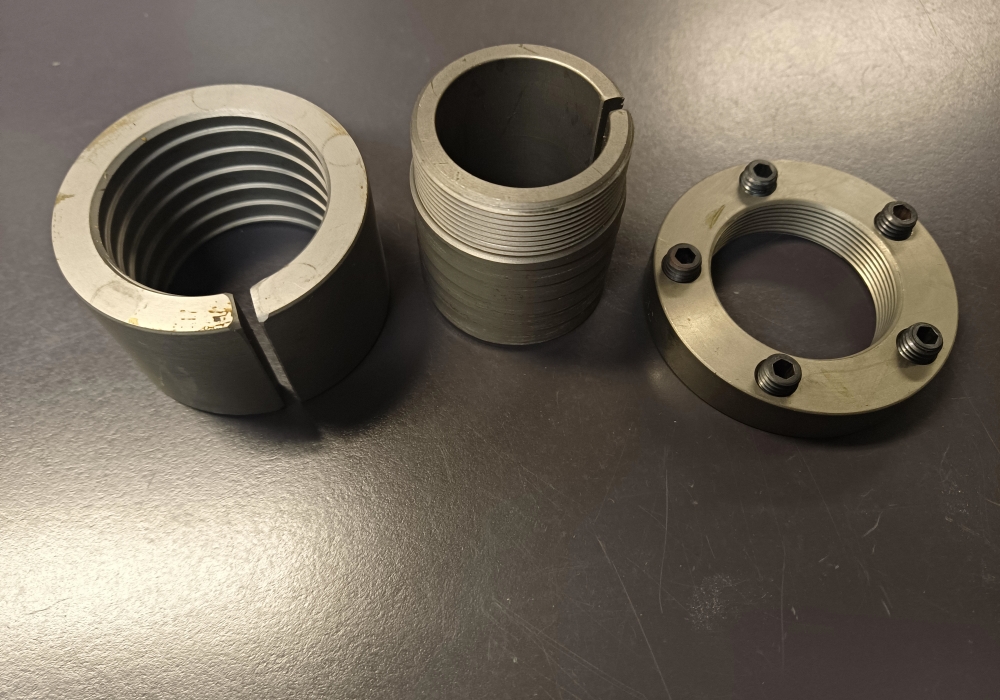

- Cutting and shaping: The material is cut and shaped into the desired size and shape using tools such as saws, lathes, or CNC machines.

- Boring and keyway cutting: The center bore of the pulley is bored out to the required size and shape, and a keyway is cut for securing the pulley to the motor shaft.

- Surface finishing: The surface of the pulley is finished using methods such as sandblasting, polishing, or painting to improve its appearance and durability.

In short, if you are not familiar with lathes or milling machines or cannot use them, you can also consider purchasing prefabricated pulleys compatible with DC motors.

How to maintain DC motor pulley ?

To maintain a DC motor pulley, it’s important to regularly inspect it for signs of wear or damage. This includes checking for cracks, chips, or other defects that could affect its performance. It’s also important to regularly clean the pulley to remove any dirt, debris, or other contaminants that could impact its operation.

In addition, it’s important to properly lubricate the pulley and the belt it’s driving to ensure smooth operation and prevent excess wear. This can be done using a specialized lubricant designed for use with pulleys and belts.

Finally, let’s introduce the cost of DC motor pulley:

The cost of a DC motor pulley can vary widely depending on factors such as the size, material, and manufacturing method of the pulley. Additionally, the cost can be influenced by the quantity of pulleys being ordered, as well as any customization or special features requested by the customer.

As a rough estimate, a simple, standard DC motor pulley can cost anywhere from a few dollars to several tens of dollars, while a larger or more complex pulley could cost several hundred dollars or more.

It’s important to note that while cost is certainly a factor to consider when purchasing a pulley, it’s also important to prioritize quality and reliability in order to ensure that the pulley will perform its intended function safely and effectively.

CONTINUE READING

Related Posts

Gears are the unsung heroes of the mechanical world, quietly and efficiently transmitting power and motion in countless devices and […]

Spur gears, with their simplicity and effectiveness, have been a cornerstone of mechanical power transmission systems for centuries. However, like […]

When it comes to connecting components on a shaft, two popular choices are Taper Lock Bushes and Keyed Bushings. These […]