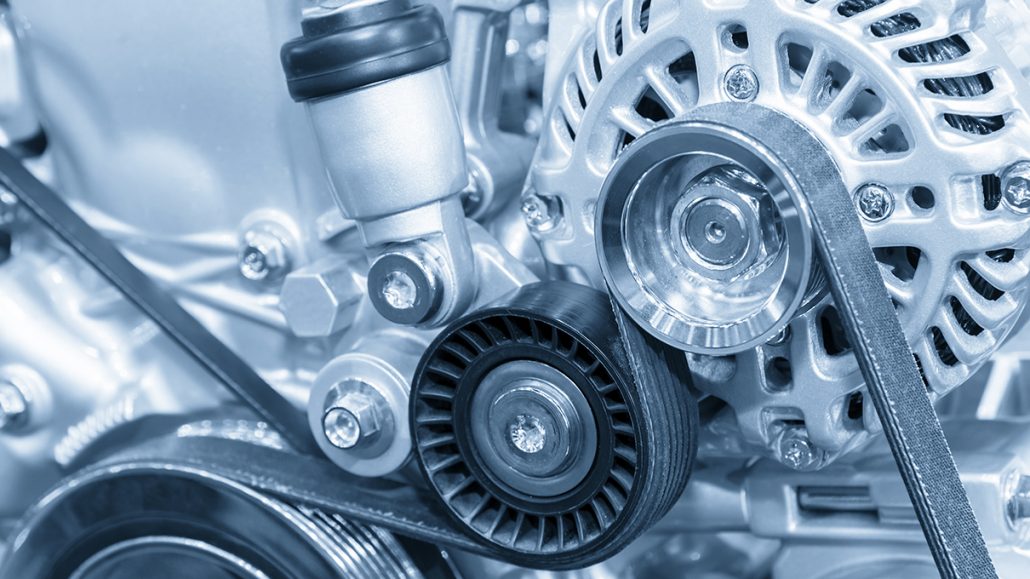

A bad engine pulley can make different types of noises such as a whining noise, screeching noise, squeaking noise, or a rattling noise. These noises can be caused by different factors such as worn-out bearings, damaged or misaligned pulleys, or a worn-out belt.

Some common causes of bad engine pulley noise are:

- Worn bearings: Over time, the bearings in the pulley can wear out, causing noise as they no longer turn smoothly.

- Misaligned pulley: If the pulley is not aligned properly, it can cause the belt to run at an angle, leading to noise.

- Loose pulley: A loose pulley can cause the belt to slip, which can result in noise.

- Damaged belt: A damaged or worn-out belt can cause noise as it moves through the pulley.

- Debris in the pulley: Dirt, debris, or other foreign objects can get caught in the pulley, causing noise.

- Faulty tensioner: A faulty tensioner can cause the belt to become loose, leading to noise.

If the engine pulley noise is not handled, it can lead to further damage to the engine and other related components. The noise can be an indication of a problem with the serpentine belt or the pulley itself. A worn or damaged serpentine belt can lead to other components not functioning properly, such as the alternator, water pump, power steering pump, and air conditioning compressor. In addition, a faulty pulley can cause the belt to slip or break, which can cause the engine to overheat or lead to other mechanical failures. It is important to address any engine pulley noise as soon as possible to prevent further damage to the engine and related components.

How to solve the problem of serious engine pulley noise?

Serious engine pulley noise may be a sign of a larger problem, so it is important to properly diagnose and address the issue. Here are some steps to help solve the problem:

- Identify the source of the noise: Use a mechanic’s stethoscope to listen to the various components of the engine while it is running. This will help identify which component is making the noise, such as the pulley, belt, or bearing.

- Inspect the pulley and belt: Check for any visible signs of damage or wear, such as cracks, chips, or missing pieces. Also check for any misalignment of the pulley or belt.

- Check the belt tension: If the belt is too loose or too tight, it can cause excessive noise. Use a belt tension gauge to ensure the belt is properly tensioned.

- Replace the pulley or belt: If the pulley or belt is damaged, it will need to be replaced. Ensure that the replacement part is the correct size and type for your engine.

- Lubricate the pulley and bearing: If the noise is coming from the bearing, it may need to be lubricated. Use a high-quality bearing grease to lubricate the bearing.

- Address any underlying issues: If the noise persists after these steps, there may be an underlying issue with the engine. It is recommended to have a professional mechanic inspect and diagnose the issue to prevent further damage.

It is important to address engine pulley noise as soon as possible, as it can lead to further damage and potentially costly repairs.

CONTINUE READING

Related Posts

In mechanical drives, gears are essential for transmitting motion, power, and torque across various applications. Two of the most commonly […]

In the world of industrial machinery, efficiency, precision, and reliability are essential. A key component in achieving these goals is […]

In the world of industrial engineering, precision and innovation are essential to staying competitive and meeting the ever-growing demands of […]